24-Apr-2025

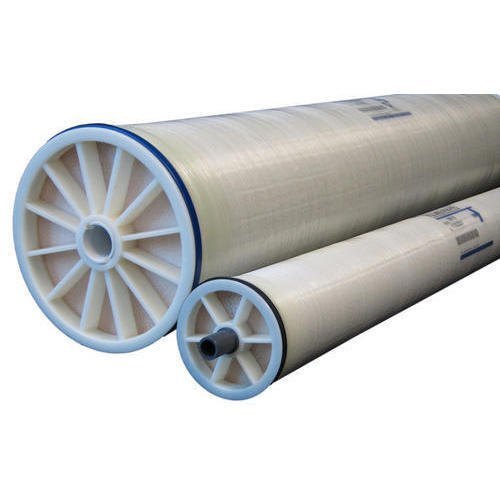

Industrial membranes are at the heart of modern water purification systems, especially in industries requiring ultrapure water or efficient wastewater treatment. Among the various types and configurations available, membranes such as 8040, 4040, and 4021 stand out due to their widespread use and high performance. These membrane types are distinguished primarily by their size and application, making them suitable for different scales of industrial operations.

What are Industrial Membranes?

Industrial membranes are semi-permeable barriers used in processes such as reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF). They allow selective separation of substances—letting water molecules pass while rejecting contaminants such as salts, bacteria, and organic matter.

Membranes are commonly housed in pressure vessels and come in standard sizes such as 8040, 4040, and 4021, which define their dimensions and, to a large extent, their flow capacity and surface.

Membrane Sizes Explained: 8040, 4040, and 4021

8040 Membrane:

The term "80" refers to 8 inches in diameter, while "40" denotes 40 inches in length. These are high-capacity membranes, ideal for large-scale industrial applications due to their large surface area and high water output (typically around 10,000 gallons per day or more depending on pressure and water quality).

4040 Membrane:

With a 4-inch diameter and 40-inch length, this size is commonly used in medium-scale commercial and light industrial systems. They provide moderate flow rates and are easier to install in compact spaces.

4021 Membrane:

This membrane has a 4-inch diameter and a 21-inch length. It is generally used in small-scale or pilot plant applications and is ideal for research, low-capacity commercial RO systems, or pre-treatment systems.

Each size serves a specific range of applications and operational needs, making it essential for engineers and technicians to select the right membrane based on capacity, space constraints, and water quality requirements.

Leading Membrane Manufacturers: DOW, Toray, and LG Chem

1. DOW (DuPont Water Solutions)

Formerly part of Dow Chemical, DuPont Water Solutions is one of the pioneers in membrane technology. Their FilmTec RO membranes are known for reliability and high rejection rates.

DOW membranes use thin-film composite (TFC) technology, which ensures durability and efficient performance under varying feed water conditions.

2. Toray Industries

A Japanese multinational, Toray is a major player in the membrane industry. Toray membranes are used globally for their durability, chemical resistance, and efficiency.

Toray membranes are also well-suited for challenging water conditions due to their tolerance to fouling and cleaning chemicals.

3. LG Chem

LG Chem's LG RO Membrane range has gained prominence due to their innovation and competitive pricing. These membranes deliver high rejection and low energy consumption, making them a good alternative in many projects.

LG membranes are known for advanced membrane chemistry that improves fouling resistance and cleaning ease.

What is the Difference Between Dow, LG, and Toray ?

All three brands—DOW, LG Chem, and Toray—use Thin-Film Composite (TFC) material in their reverse osmosis membranes. TFC is the industry standard because it offers high salt rejection, good permeability, and durability under various operating conditions. It typically consists of a polyester base layer, a microporous polysulfone layer, and an ultra-thin polyamide selective layer that performs the actual filtration.

Although the base material is the same, the differences come from how each brand engineers their TFC layers:

Applications of Industrial Membranes

Membranes work as an essential component for various industrial sectors:

Each application demands specific membrane types, configurations, and cleaning protocols, which is why understanding membrane sizes and capabilities is so important.

How to Choose the Right Membrane?

When purchasing an RO membrane, consider the following points in mind:

Popular Companies Selling These Membranes

Several companies supply high-quality industrial membranes to match diverse industry needs. Here are some of the leading distributors and manufacturers:

1. Pearl Water Technologies

Pearl Water Technologies is known as one of the leading and trusting companies for water and wastewater treatment service in India. They offer a wide range of industrial RO membranes including 8040 and 4040 sizes. Known for quality assurance and excellent after-sales support, Pearl provides:

Their membranes are used in industries ranging from manufacturing to hospitality, ensuring optimal performance and long service life.

2. Pure Aqua Inc.

Based in the U.S., Pure Aqua is a global provider of water treatment systems and components. They supply membranes from DOW, Toray, and Hydranautics, suitable for projects worldwide.

3. GE Water (Now SUEZ Water Technologies)

SUEZ offers high-performance RO membranes for various industrial and municipal applications, focusing on energy efficiency and long-term reliability.

Conclusion

Industrial membranes like 8040, 4040, and 4021 play a vital role in water treatment across industries. Leading manufacturers like DOW, Toray, and LG Chem offer a variety of options tailored to different scales and requirements. Whether you're dealing with high-volume industrial systems or compact commercial setups, selecting the right membrane is key to achieving efficiency and reliability.

Investing in the right membrane technology not only ensures water quality but also boosts the overall sustainability of your operations.

Leave A Comment